|

Structural Health Monitoring is the process of implementing a damage detection strategy for civil and mechanical engineering infrastructure.

The SHM process involves:

After extreme events, such as earthquakes or storm loading, SHM is used for rapid condition screening and aims to provide, in near real time, reliable information regarding the integrity of the structure. |

Collapse of Sungsu Bridge (Korea, 2004) could have been prevented by SHM

|

STRUCTURAL HEALTH MONITORING PROCESS

|

Structural Health Monitoring process includes:

1.Operational evaluation Defines the damage to be detect and begins to answer questions regarding implementation issues for a structural health monitoring system. 2. Data acquisition Defines the sensing hardware and the data to be used in the feature extraction process. 3. Feature extraction The process of identifying damage-related information from measured data. 4. Statistical model development for feature discrimination Classifies feature distributions into damaged or undamaged category. |

Data Cleansing

Data Normalization Data Fusion Information Condensation (implemented by software and/or hardware) |

WIRELESS SMART SENSOR NETWORKS

|

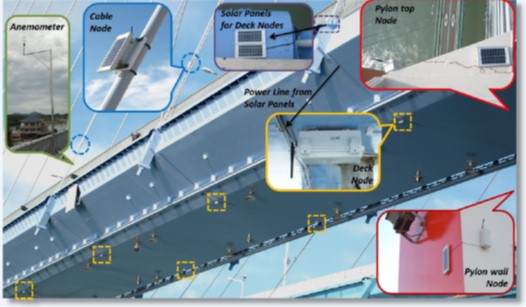

Recent advanced sensor technologies have enabled SHM using wireless smart sensor networks (WSSNs), which is a promising alternative to the traditional wired SHM approaches. The smart sensors are typically small, inexpensive, and capable of wireless communication and onboard computation, addressing many of the concerns regarding wired monitoring. For example, easy installation and the associated reduction of installation cost, multi-hop communication, and decentralized in-network data processing are available with recent advances of WSSN; these attractive features enable the development of scalable monitoring systems and dense sensor networks.

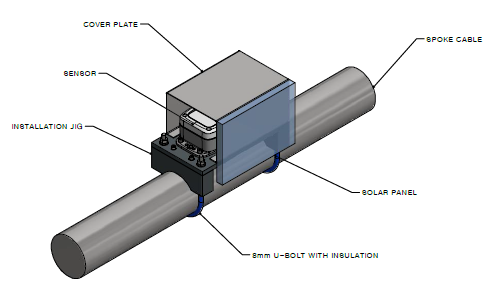

TESolution has extensive experience in setting up Monitoring System with wired/wireless sensors and also has proven track record of System Identification for structures for installation of vibration control devices as well as System Identification to check the performance of the vibration control device after the installation. Most recently, TESolution won the bid for the Monitoring System for the Spoke Cables(including provision of 192 Xnode Smart Sensors) of a giant ferris wheel currently being built in Dubai. |

WSSN for Jindo bridge monitoring (Korea, 2009~2012)

|

EXAMPLE OF FIELD APPLICATION

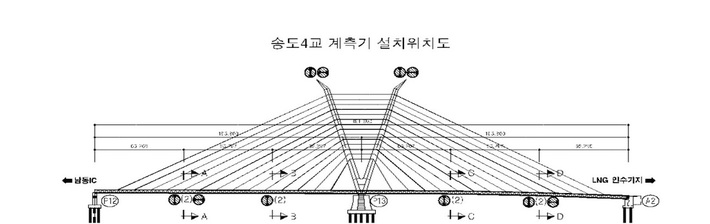

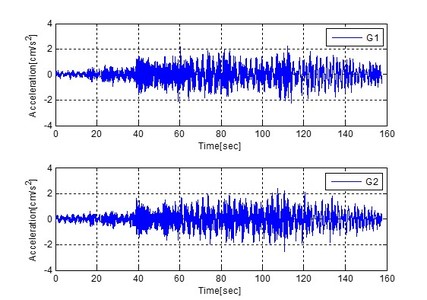

4th Songdo Bridge (2015)

EXAMPLE OF FIELD APPLICATION

Giant Observation Wheel under construction in Dubai (2016)

© 2016 TESolution Co. Ltd.

142 Seungjin-gil, Gongdo-eup,

Anseong-si, Gyeonggi-do,

17563, Korea

TEL +82-31-658-2906 | FAX +82-31-658-2908

General Inquiries : tesolution@tesolution.com

Home | Vibration Control technologies | Wind Tunnel Testing for Buildings | Wind Tunnel Testing for Bridges | Sitemap

142 Seungjin-gil, Gongdo-eup,

Anseong-si, Gyeonggi-do,

17563, Korea

TEL +82-31-658-2906 | FAX +82-31-658-2908

General Inquiries : tesolution@tesolution.com

Home | Vibration Control technologies | Wind Tunnel Testing for Buildings | Wind Tunnel Testing for Bridges | Sitemap

TESolution

Total Engineering Solution in Wind Engineering and Vibration Control

142 Seungjin-gil, Gongdo-eup, Anseong-si, Gyeonggi-do, 17563, Korea

Tel : 82-31-658-2906

Fax : 82-31-658-2908

Contact : tesolution@tesolution.com

Copyright © 2016 TESolution

Total Engineering Solution in Wind Engineering and Vibration Control

142 Seungjin-gil, Gongdo-eup, Anseong-si, Gyeonggi-do, 17563, Korea

Tel : 82-31-658-2906

Fax : 82-31-658-2908

Contact : tesolution@tesolution.com

Copyright © 2016 TESolution